Content

Off-line PCBA Selective Wave Soldering Machine

❙ Introduce of Selective Wave Soldering Machine

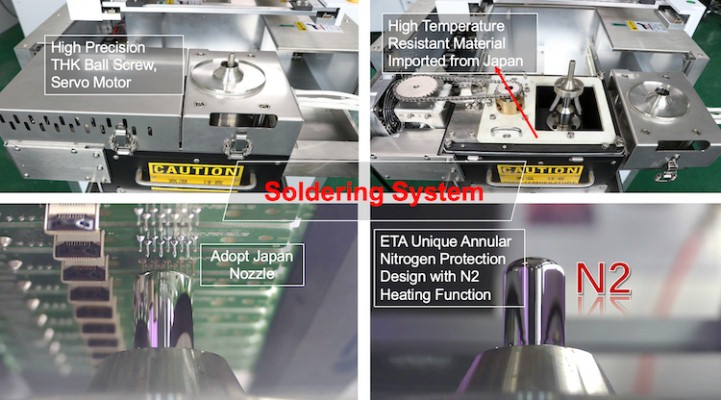

Economical and energy-saving nitrogen wave soldering machine, off-line selective wave soldering machine, high quality wave soldering machine, for PCBA soldering.

ETA SS-330 series off-line selective wave soldering is a high-quality machine developed and designed in Japan and assembled in China. It has been used in many Japanese enterprises and has been recognized by customers.

Selective wave soldering is a special form of wave soldering invented to meet the development requirements of through-hole components welding. It is mainly suitable for the soldering of through-hole components in high-end electronic products. For example: military electronic products, automotive electronics, switching power supply products and other industries which require higher soldering reliability.

ETA SS330 selective wave soldering is a high performance equipment developed in Japan and assembled in China.

Features:

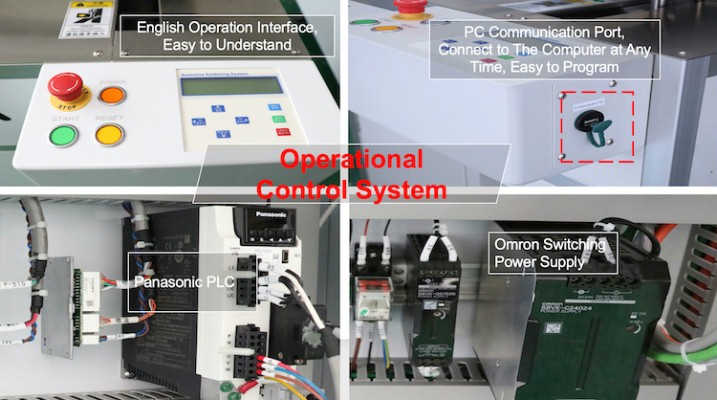

1, Spray control: computer control or manually adjust switch, precise control the spray time, spray speed, economy and environmental protection, digital FLUX flow, spray flow, angle, density, width and other parameters can be recorded.

2, User-friendly design: fault detection (such as heaters abnormal alarm, etc.), regular maintenance reminders, economy functions, emergency manual transmission function and tool-free maintenance, reduce equipment failure rates.

3, Core components: using imported components to ensure long-term stability of equipment operation.

4,It can control the solder quantity, soldering time and solder quantity of each solder spot.

5, Program creation is simple, using pictures or Gerber data to make production program.

6, Nozzle can be selected according to the size of soldering point, and there is no need for fixture to protect non solder parts.

7, Energy saving, low power consumption, 2kw working power, 16kg solder pot, low material input cost,Solder slag less than 200g/ 8h.

❙ Specification of Selective Wave Soldering Machine

| Model | ETA SS-330F (Flux Spraying Machine) |

| Flux Storage Tank | 0.7L |

| Flux Support | Flux Alarm, Automatic |

| Spray Nozzle | Japan ST-6SK |

| Spray Precision | 0.1mm |

| Moving Speed | 10~200mm/sec |

| Spray Height Adjustment | Manual(Adjustment Range:20±5mm) |

| Spray Flow Control | Electronic Flow Meter |

| Exhaust Capacity | 8m3/min(Φ98mm) |

| Model | ETA SS-330S (Selective Soldering Machine) |

| Control Motor | PC+ Microcomputer Controller |

| Nozzle Inner Diameter | Φ 4-20mm |

| Max. Wave Height | 5mm |

| Wave Height Control | Step Motor RPM |

| Solder Pot | SUS316+ Surface Treatment |

| Solder Capacity | 16 kg |

| Heating Tube Quantity | 6 pcs |

| Max. Temperature | 350°C |

| Warm-up Time | Approx.40min (setting 270°C) |

| PCB Size | 50*50 ~ 250*330mm(380*460 Optional) |

| PCB Top Clearance | 100 mm |

| PCB Bottom Clearance | 35 mm |

| PCB Weight | 5 kg |

| PCB Thickness | 0.8-3.0mm |

| Clearance from PCB edge | 5 mm |

| Transport Height | 850 ±25mm |

| N2 | Purity of N2: 99.99%, 0.4~0.5 MPa,25 L/min, Outer diameter Φ6mm |

| Air Pressure | 4.5~6Kg/cm2 |

| Power Supply | 220±10%, 50/60HZ, 3.5Kw |

| Dimension | L830*W630*H1290mm |

| Weight | Approx.: 260kg |

❙ ETA Customer Factory

▽ ETA Korea DIP line with wave soldering machine

▽ ETA Russia DIP line with wave soldering equipment

▽ ETA Ecuador DIP line with PCB soldering machine

❙ Company Profile

Successful Experience:

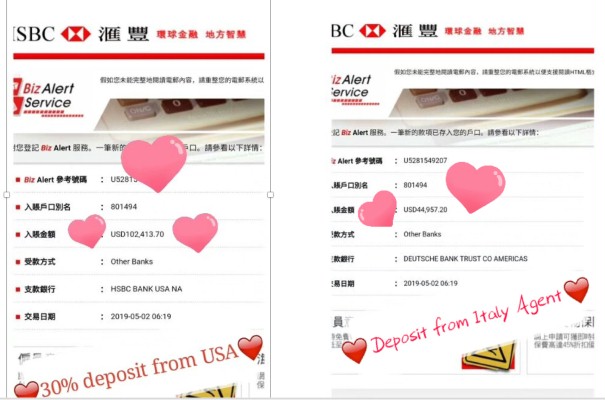

Eta's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solutions for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

❙ ETA SMT Machine Exhibition

❙ Wave Soldering Machine Certificate

❙ ETA Global Service

❙ Customers' Feedback

❙ FAQ

❙ Selective Wave Soldering Machine Video