Content

❙ Introduce

1.Nozzle: Japan Kuroda Seiko nozzles, adjustable atomizing area, ensuring the long time spray uniformity and reliability.

| Model | W4 | W3 | W2 |

| Dimension:(mm) | 4200X1250X1500 | 3600X1250X1500 | 2900X1160X1500 |

| Weight(kg) | Approx.1500kg | Approx.1200kg | Approx.790kg |

| Power Supply | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz |

| Startup Power | 32kw | 24kw | 16kw |

| Operation Power | 12kw | 9kw | 7kw |

| Control System | PLC | ||

| Spray System | |||

| Transmission Method | Step motor | ||

| Spray Pressure | 0.25Mpa--0.4Mpa | ||

| lux flow | 10--100ml/min | ||

| Exhaust Diameter | Φ200mm | ||

| Exhaust Capacity | 25m3/min | ||

| Preheating System | |||

| Preheating Mode | Hot air | ||

| Control Mode | PID + SSR | ||

| Preheating Zone | 4 | 3 | 2 |

| Preheating Length | 1800mm | 1600mm | 1200mm |

| Preheating Temp. | (Room Temperature)-250°C | ||

| Warm-up Time(min) | Approx.15min (setting 150°C) | ||

| Conveyor System | |||

| PCB Size:LxW(mm) | Min:80x60mm; Max:400x300mm | ||

| Conveyor Speed | 0-2000(mm/min) | ||

| Conveyor Height | 750+/-20 (mm) | ||

| Finger | Double hook claw (Standard) | ||

| Conveyor width control | Manually | ||

| Conveyor Angle | 4~7degree | ||

| Soldering System | |||

| Solder Pot style | Mechanical Motor drive | ||

| Solder Pot Material | Full Titanium (Standard FT) | ||

| Solder pot temperature | 300°C | ||

| Solder pot capacity | Lead-free 350kg | Lead-free 300kg | Lead-free 250kg |

| Other | |||

| Finger cleaning system | Brush | ||

❙ Related Keywords

Wave Soldering Machine,Wave Soldering Machine Manufacturer,Selective Wave Soldering,Selective Wave Soldering Machine,Mini Wave Soldering Machine,Wave Soldering Equipment,PCB Wave Soldering Machine,PCB Wave Soldering,PCB Soldering Machine,PCB Soldering Dual Wave Machine,SMD Wave Soldering,Lead Free Wave Solder Machine,Automatic Wave Soldering Machine,SMT Wave Soldering Machine,Dual Wave Soldering Machine,DIP Wave Soldering Machine,Through Hole Wave Solder.

❙ ETA Customer Factory

❙ Company Proflie

Shenzhen ETA Technology Co., Ltd. Expert in Making Customized High Quality SMT LED Pick and Place Machine, SMT LED Reflow Oven, SMT LED Stencil Printer, SMT Production Line, LED Assembly Line With More Than 23 Years Experience.

Our Goal is to Provide Customers With the Best Service Possible and to Produce Excellent Quality Products That Will Meet or Exceed Your Expectations.

Successful Experience:

Eta's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

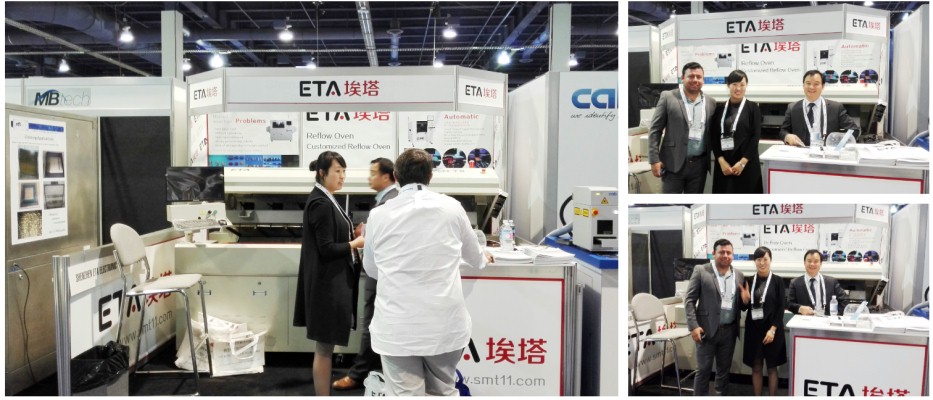

❙ ETA Exhibition

❙ ETA Products Certificate

❙ ETA Global Service

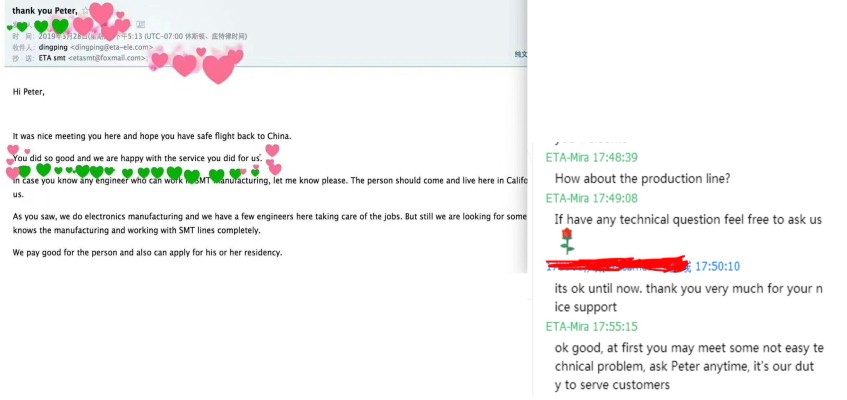

❙ Customers' Feedback

❙ FAQ

❙ Main Keywords

Reflow Oven,Pick and Place Machine,SMT Machine,SMT Line,Wave Soldering Machine,Reflow Soldering Oven,SMT Equipment,SMT Pick and Place Machine,Chip Mounter,PCB Cutting Machine,SMT Reflow Oven,Pick & Place Machine,SMD Soldering Machine,SMT Aoi,SMT Conveyor, SMT Solutions, Chip Shooter, PCB Cleaning Machine, Reflow Machine, PCB Soldering Machine, SMT Assembly Line, SMT Stencil Printer, PCB Reflow Oven, Reflow Soldering Machine, SMT Oven, Pick n Place Machine, SMT Production Line, Solder Paste Printer Machine, SMT Screen Printer, LED Pick and Place Machine, SMT Line Machine, LED Production Line, SMT Nozzle Cleaning Machine, LED TV Production Line.

If You Could Not Find Any Similar Items You Want, You May Send Some Photos to Us. Because Our Catalog and Website Haven't Included All of Our Products.

❙ DIP Soldering Machine Video